Decommissioning, retrofitting or replacing fireplaces in accordance with the 1. BImSchV

In 2010, the „1. BImSchV“ came into force in Germany. This ordinance specifies replacement obligations (retrofitting or decommissioning where necessary) for single-room firing installations for solid fuels.

The ordinance is available to everyone online free of charge, and chimney sweeps, associations and the media have been providing continuous information on the topic since 2010.

German version of the 1. BImSchV:

Due to the fact that the last date for retrofitting or decommissioning is 2024, we are receiving a flood of telephone and written inquiries. Many fireplace owners are worried due to false reports in the media, need proof of compliance with limit values or are looking for consulting.

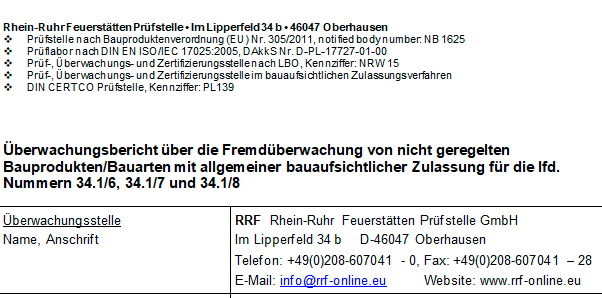

Our notified body is not the right contact for this.

As a testing and certification body notified by the European Commission, we are not permitted to make test results or documents accessible to third parties or to make statements to third parties about tests or certifications carried out by us, as these are legally the property of the respective client/manufacturer. We are also not permitted to provide consulting on products tested or certified by us.

If you have any questions, you should first contact the distribution channel through which the construction product was purchased (e.g. specialist dealer, hardware store, shipping chain).

If this cannot provide information, please contact the manufacturer listed on the type plate or documents.

Even if manufacturers no longer exist or cannot be found, this does not release us from our duty of data protection and confidentiality.

The following transitional periods are listed in the 1. BImSchV:

| Date on the type plate | Date of decommissioning, retrofitting or decommissioning |

| Up to and including December 31, 1974 or date can no longer be determined | December 31, 2014 |

| January 1, 1975 to December 31, 1984 | December 31, 2017 |

| January 1, 1985 to December 31, 1994 | December 31, 2020 |

| January 1, 1995 to including March 21, 2010 | December 31, 2024 |

The current phase affects fireplaces that were marked between January 1, 1995 and March 21, 2010 (date/year on the type plate). These must be decommissioned, retrofitted or replaced by a new low-emission fireplace by December 31, 2024 if the existing fireplace does not comply with the applicable limit values.

For all fireplaces that are affected by a previous phase but have not yet been considered, immediate action must be taken by the district master chimney sweep.

The Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV) assumes that up to approx. 4 million fireplaces are affected by this legal regulation in the 1. BImSchV. The number of inquiries we receive is correspondingly high.

Please understand that we are unable to answer detailed questions for the reasons mentioned above.

trendfairs

trendfairs